Login

Contact

Description

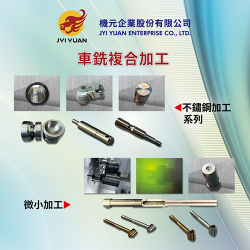

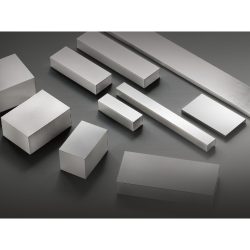

The features of car milling compound precision machining parts are as follows:

High Precision Machining: Multi-axis machining technology enables high-precision part manufacturing, suitable for parts with extremely high precision requirements. This is because multi-axis machining can perform complex path movements, reducing the number of workpiece clamping and clamping errors.

Processing of Complex Geometric Shapes: Multi-axis compound machining can handle complex geometric shapes and structures, which are difficult to achieve with traditional three-axis or four-axis machining. This makes it ideal for manufacturing high-complexity parts in industries such as aerospace, medical devices, and automotive.

Multi-functional Machining: These machines typically integrate multiple machining functions such as turning, milling, drilling, and tapping, enabling multiple processes to be completed in one clamping, thus improving machining efficiency and part consistency.

Shortened Machining Time: Since multiple processes can be completed in one clamping, the time for repositioning and calibration is significantly reduced, thereby shortening the machining cycle time and improving production efficiency.

Reduced Tooling Requirements: Multi-axis machines can contact workpieces from different angles, reducing the need for special tooling, thereby reducing production costs and design complexity.

High Rigidity and Stability: Multi-axis machining centers typically have higher machine rigidity and stability, able to handle high-speed, high-load machining environments, ensuring machining quality.

6. Flexibility and Adaptability: Multi-axis compound precision machining centers have high flexibility, able to adapt to different types and scales of production requirements, ranging from small batch customization to large-scale production.

7. Reduced Manual Intervention: Due to the high level of automation, multi-axis compound machining can reduce the intervention of operators, thereby reducing the risk of errors and improving machining consistency and stability.

These features make multi-axis compound precision machining an indispensable technology in modern manufacturing, especially in high-precision and high-complexity fields.

High Precision Machining: Multi-axis machining technology enables high-precision part manufacturing, suitable for parts with extremely high precision requirements. This is because multi-axis machining can perform complex path movements, reducing the number of workpiece clamping and clamping errors.

Processing of Complex Geometric Shapes: Multi-axis compound machining can handle complex geometric shapes and structures, which are difficult to achieve with traditional three-axis or four-axis machining. This makes it ideal for manufacturing high-complexity parts in industries such as aerospace, medical devices, and automotive.

Multi-functional Machining: These machines typically integrate multiple machining functions such as turning, milling, drilling, and tapping, enabling multiple processes to be completed in one clamping, thus improving machining efficiency and part consistency.

Shortened Machining Time: Since multiple processes can be completed in one clamping, the time for repositioning and calibration is significantly reduced, thereby shortening the machining cycle time and improving production efficiency.

Reduced Tooling Requirements: Multi-axis machines can contact workpieces from different angles, reducing the need for special tooling, thereby reducing production costs and design complexity.

High Rigidity and Stability: Multi-axis machining centers typically have higher machine rigidity and stability, able to handle high-speed, high-load machining environments, ensuring machining quality.

6. Flexibility and Adaptability: Multi-axis compound precision machining centers have high flexibility, able to adapt to different types and scales of production requirements, ranging from small batch customization to large-scale production.

7. Reduced Manual Intervention: Due to the high level of automation, multi-axis compound machining can reduce the intervention of operators, thereby reducing the risk of errors and improving machining consistency and stability.

These features make multi-axis compound precision machining an indispensable technology in modern manufacturing, especially in high-precision and high-complexity fields.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry